Custom Old West Saddle Tree

Not authentic process, but authentic and historically accurate result.

For years now, I've been planin' on learnin' how to make saddle trees. Over the years I've gotten to know award winning saddle tree and saddle maker, Jon Watsabaugh. When I was overwhelmed with last minute gun rigs for "3:10 to Yuma", it was Jon I turned to to get everything done on time.

Jon and I have talked for years about developing a line of Old West saddle patterns, using Jon's trees as the foundation. We're still workin' on that. But, late in December of '09, I finally got a chance to spend a day in Jon's shop.

I've used Jon's trees for years. They have been the bedrock for historical saddles used in PBS's "Texas Ranch House", and many of my authentic Old West saddles. In fact, since I first used one of Jon's trees, I've never even thought of using anything else.

I've always been happy to pay Jon's goin' rate for a custom tree. Right now, they run about $550 each. After spending a day with Jon in his shop, I feel like I'm robbin' him. I might not be able to sleep at night.

Jon

A few of the trees Jon has in production.

Jon laminates the stock each of his bars will be carved from. Only a few of the best tree makers use this procedure. It adds time and expense to the operation, but the durability of laminated bars can't be achieved with a single block of wood. Jon lays out his bar pattern for the saddle I want. He then begins the carve the bar out of his laminated stock.

I want to re-create a frontier-built saddle from the 1830s, in what would eventually become New Mexico. The opening of the Santa Fe Trail in 1821 strongly influence Missouri saddle makers. Soon, you could find "Spanish" saddles being made in Missouri saddle shops.

Young Kit Carson was apprenticed to one of these Missouri saddle makers. Kit ran away from his master and made his way down the Santa Fe Trail as a wrangler tending the extra livestock.

His master, by law, had to post a notice on the runaway apprentice. But, he delayed as long as he could, posted misleading information, and offered a reward of only One Cent for Kit's return. Within a year, his apprentice master, David Workman, succumbed to the lure of the Santa Fe Trail, and followed Kit's lead south.

I wanted Jon to make me a tree similar to the saddle pictures to use for my reproduction.

Jon will continue to work on the tree, then bring it by for me to check out. After all the specifics on the style are established, Jon will rawhide it in the traditional pattern of early frontier saddles. As I get more pictures, I'll continue posting the story. This is goin' to be one spectacular saddle when it is done!

Through a marvelously complicated and involved series of measurements, patterns, and jigs, Jon carves the bars. The genius of Jon's system is it's versatility and replicate-ability. Jon can adapt his bar styles and rock to a limitless variety of horses' backs...and repeat the process accurately from tree to tree. The vast majority of tree makers have set bars you can choose from. Jon does as well, but he has the engineering capability to adapt everything he make to a specific horse, rider, and style. I intend on making at least one of my own trees someday, the old-world way, but after seeing the process used by Jon to get just the right dimensions and fit, it'll be infinitely easier, more productive, and result in a higher quality of product, to have Jon make all my production trees.

Jon laminates the fork of the saddle so it can be drying as he continues to rough-out the bars. By the time he is finished with the bars, the fork is ready to be carved out of the laminated block. Again, with an intricate series of measurements, patterns and jigs, Jon precision-cuts the working angles into the fork and begins to rough-out the shape.

Jon fits the bars to the most amazing adjustable jig I've seen him think up yet! He cuts the sections to build the laminated cantle so it will be dry when he is ready for it. Then, with a little more carving on the fork, Jon fits it on the bars in the adjustable jig. The joints fit perfectly! There is still a lot of carving to do, but the elements of the tree are fitting together, literally like clock-work.

Jon begins the complicated process of laying out the angles, size, and dish of the cantle. He starts carving away at it on his band saw. Then, he contours the dish. After that, Jon slaps it in another home-made jig and cuts the precision angle that will fit into the notch in the bars.

By the end of the day, Jon has the basic tree roughed-out and fitted together with precision. There is still more carving and shaping to do. The details of the style that will mark it as an authentically reproduced 1800s saddle still have to be incorporated. Jon would have gotten a lot farther, but I was a constant distraction.

If you would like to talk with Jon about building you a custom saddle tree, you can contact him at:

Jon Watsabaugh

4115 SE 15th Street

Des Moines, IA 50320

Business Mobile: 515-240-9840

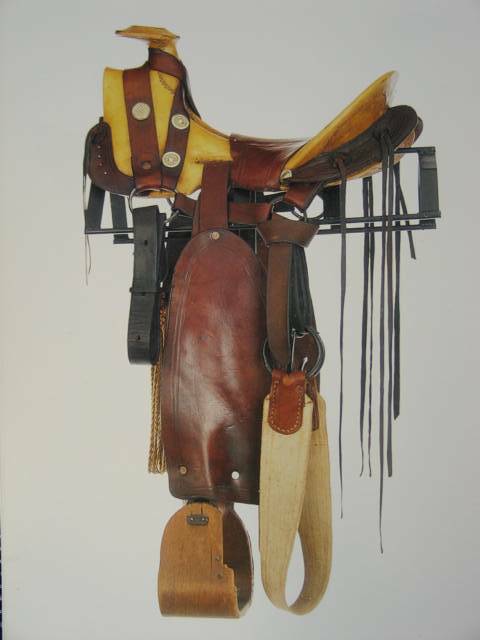

1850s or 60s double rigged stock saddle. While it is a beautiful saddle, I was just using it to illustrate to Jon some of the details I want in my 1830s tree...

though, I might change my mind...